Technology

The Sparter incorporates unique patented technology which makes it possible to detect asparagus underground, as a result of which quality and quantity are improved and the cost price is halved. The method of picking has also been patented.

How the Sparter works :

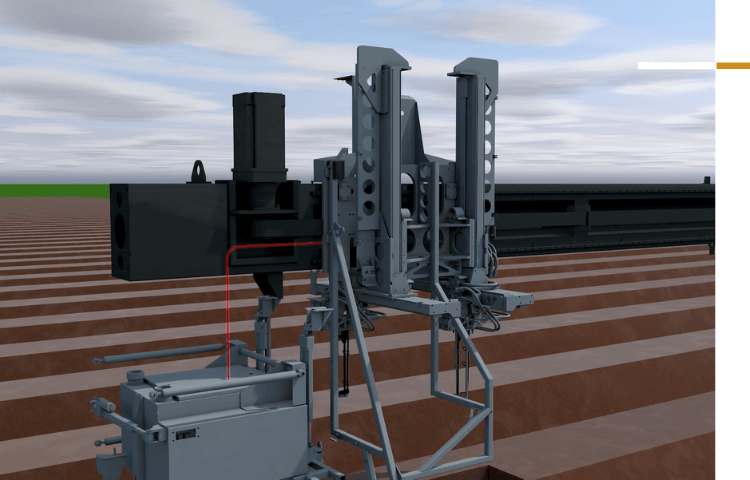

The plastic is picked up and placed back on the bed behind the machine.

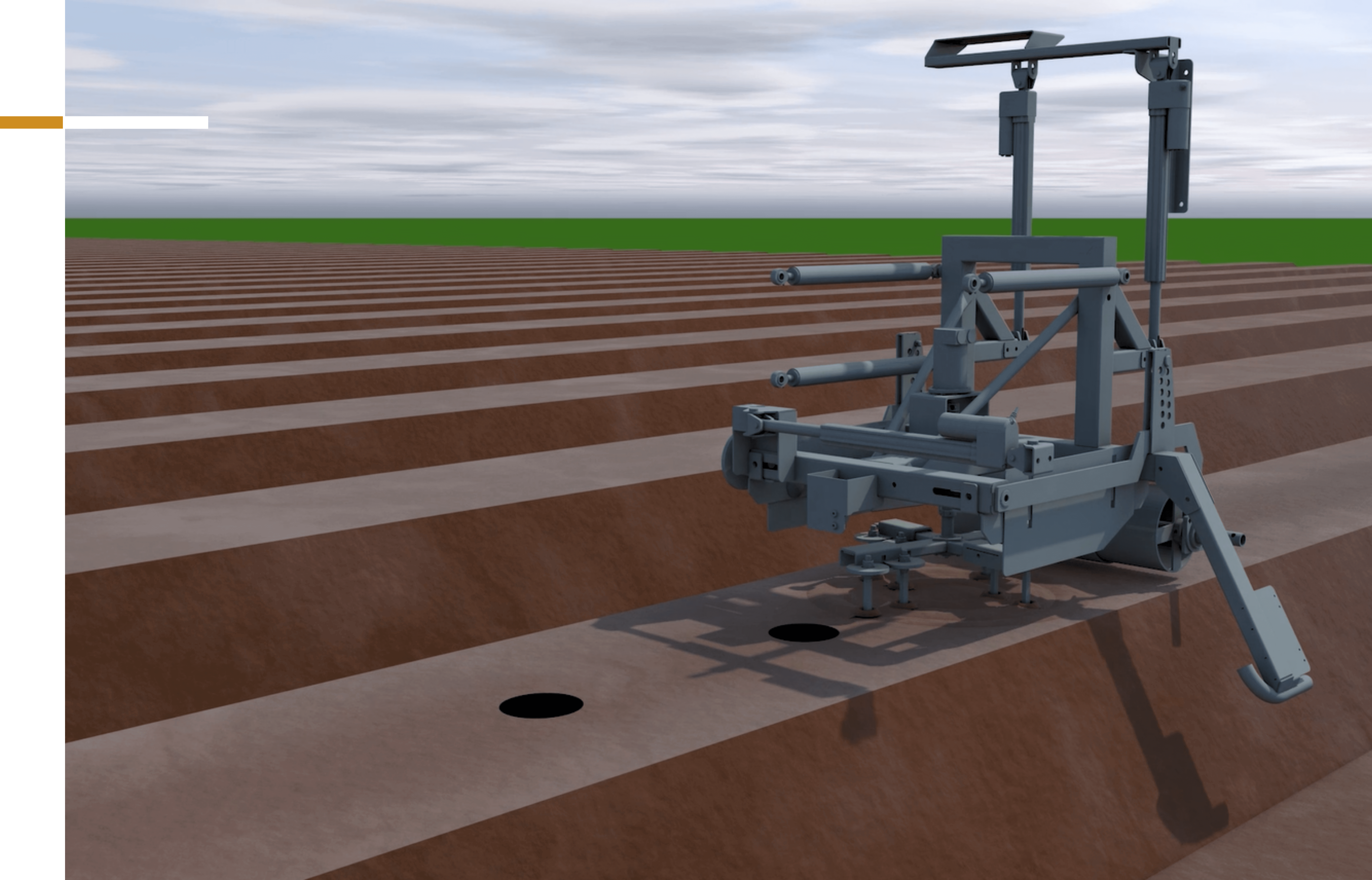

Using an earth ski, a minute detection signal is injected into the soil making the asparagus visible for the sensors.

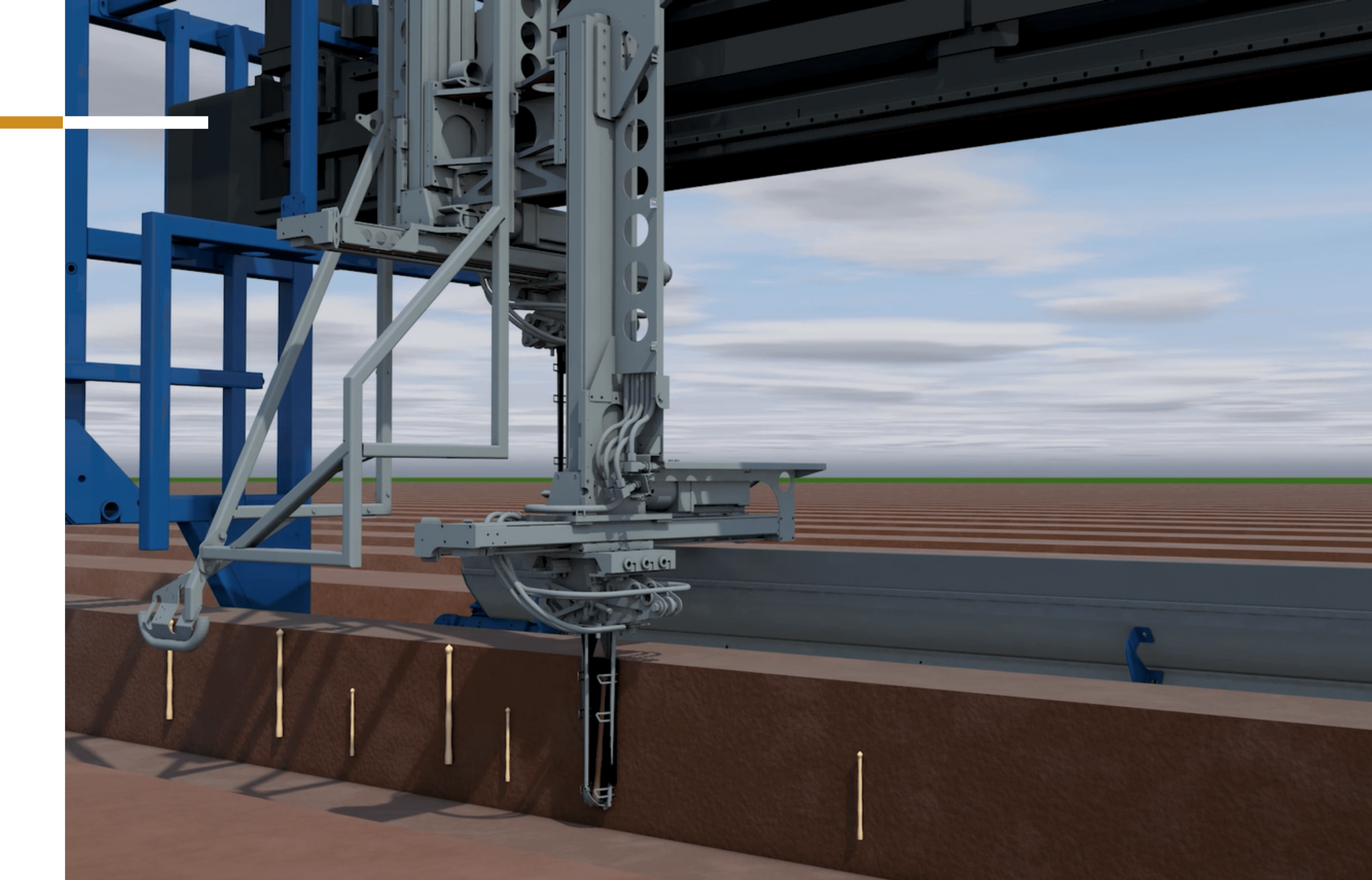

The detection module incorporates a number of feelers with sensors which can move through the soil at variable depths. When a feeler detects an asparagus spear via the sensor, the coordinate is calibrated and the feeler is withdrawn at high speed to prevent the asparagus being damaged.

The coordinate measured is transmitted to the harvesting robot.

Which picks the asparagus from the top side of the bed, removing it in one swift action.

During this picking action, the robot moves at a speed which is the same as that of the machine, only in a different direction. The machine therefore moves forward at a constant speed.

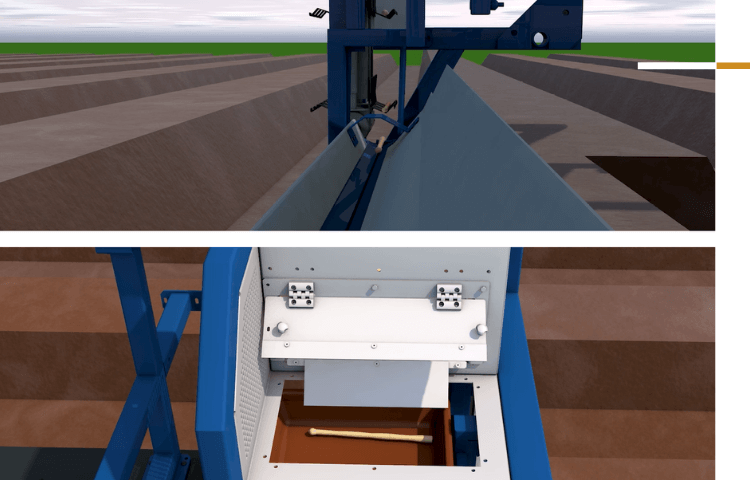

Asparagus that have been picked are placed on a conveyor belt and transported to a receptacle.

Finally, the sand bed is homogenised to prevent future asparagus spears becoming bent.

There are two robots per row to increase the capacity of the machine. This method of harvesting allows the frequency of picking to be reduced from once a day to once or twice every three days. Because of its underground detection system, the Sparter needs no lights. This means that picking can take place by day and by night. The Sparter also lifts the plastic and replaces it at the rear.

Due to the underground detection, the asparagus is detected and picked before its head protrudes above the sand bed, thus preventing violet discolouration and open heads. The repair of the sand bed means that the asparagus also stay upright for the whole of the season. This results in more A-class sorting. The picking method using the harvesting robot from above prevents damage to those asparagus spears under the soil which are not sufficiently large. In the case of hand picking, underground damage can lead to losses of up to 30%. With the Sparter’s underground detection system, the underground damage is significantly less.