Sparter

Specifications

sand beds Specification

Sparter Specification

trailer Download

leaflet

-

Sparter is one of a kind and gives growers the following benefits:

- Better quality asparagus due to a patented underground detection system. This means that the asparagus is harvested before emerging from the soil, so avoiding violet discoloration and reducing the number of open heads.

- Higher yields through improved quality because the asparagus harvester restores the sand bed after picking, so reducing the percentage of bent spears.

- With subsurface detection, the harvesting frequency can be reduced to 1x/3 days, thus tripling the harvesting capacity compared to a system with detection upon surfacing.

- Subsurface detection does not require a light source, which means the cultivator can work day and night, as required. This means machine capacity can be increased yet further.

- Automatic speed control for optimum use of 2 cutting robots per row.

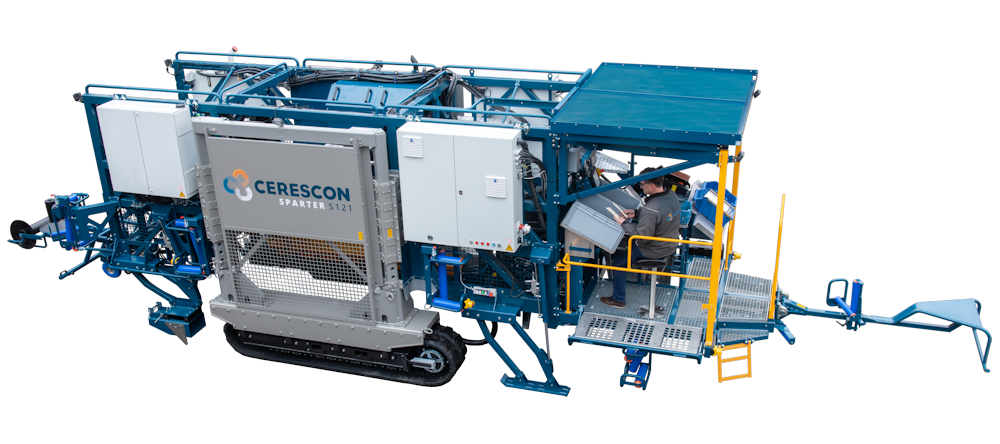

- Easily transportable by road using a trailer.

- Small turning circle due to compact dimensions. This machine can negotiate a 6-metre headland turn.

- Caterpillar tracks for reducing soil compaction and extra stability.

- This machine can be driven by one operator.

- The 1-row Sparter can be adapted for use with mini-tunnels.

- Capacity: depending on the asparagus variety, length of the asparagus beds, weather conditions and harvesting frequency, approximately 0.3 ha/hour.

Harvesting with the Sparter demands a number of requirements on the part of your sand beds. Download the specifications for the sand beds here .

Because situations vary from grower to grower, investment payback times can differ. On average, the costs of harvesting by machine can halve those of hand-picking. Cerescon will be happy to help calculate the payback time for individual situations. Interested? If so, submit your contact details using the Contact form, adding the subject-heading “Payback calculation” and the name of your company. Cerescon will get back to you within 7 days to request more detailed information. We will send you our calculation within just a few days.

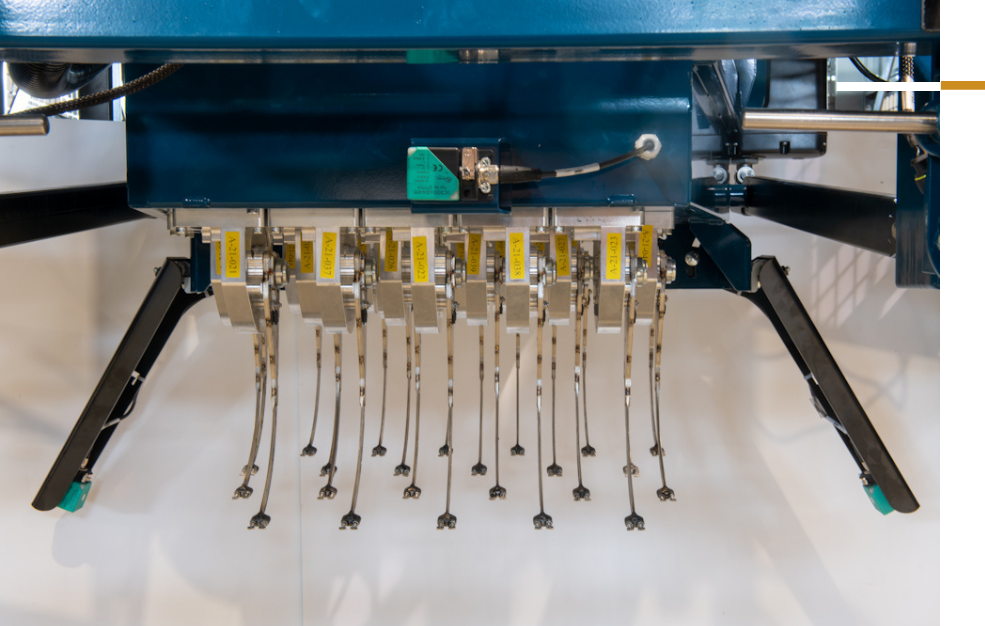

Detection

Cerescon has a unique patented detection method: advanced proximity sensors are able to detect the asparagus underground without coming into contact with the asparagus. A rapid retraction mechanism prevents contact with the asparagus so that it remains undamaged. At this point, the coordinates of the asparagus are transmitted to a harvesting robot.

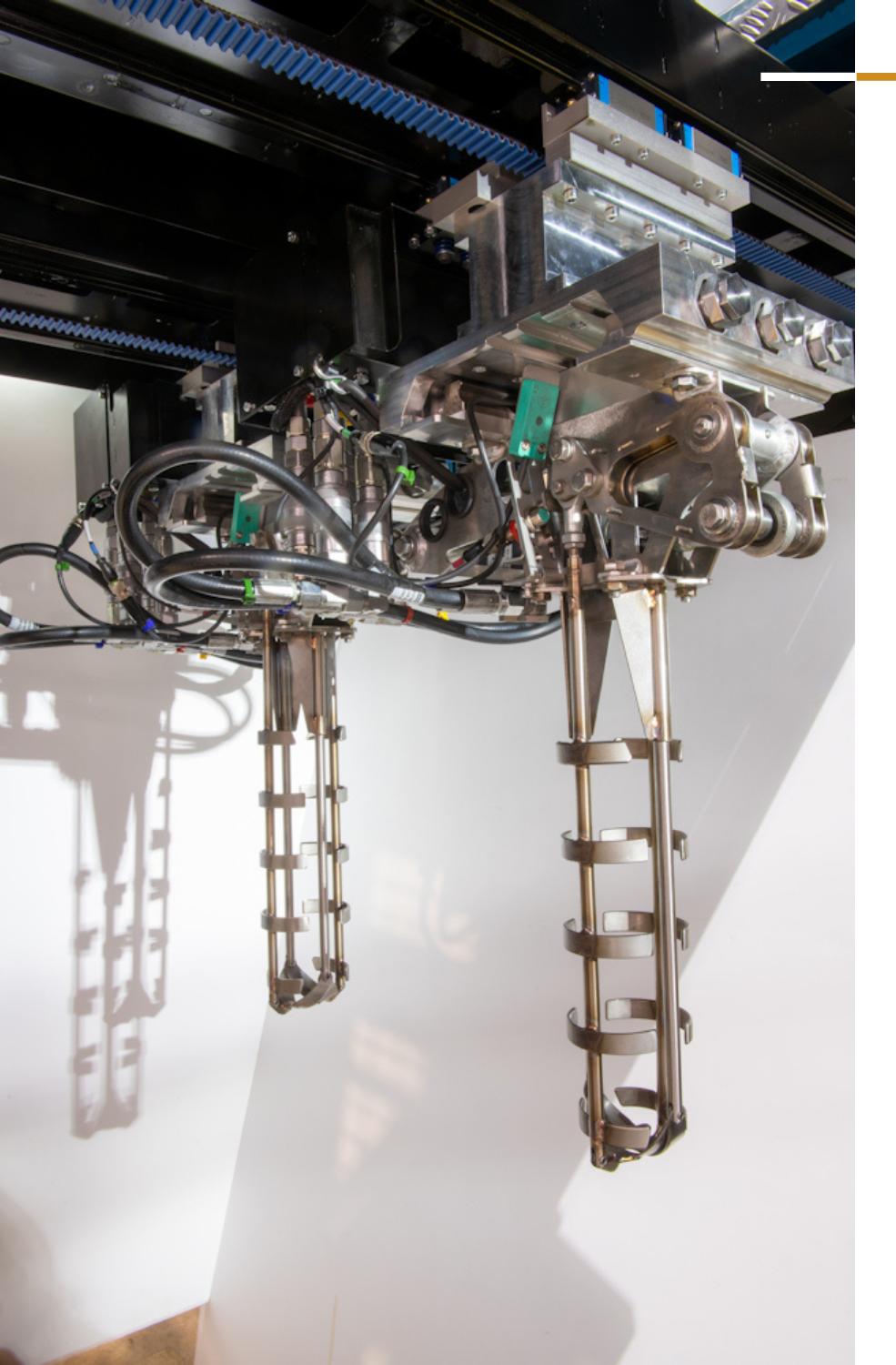

Picking

The patented harvesting robot (2 per row) picks the asparagus from the top of the bed in one single movement and places it on a conveyor. The tractor pulling the machine drives at a constant speed so optimising machine capacity. The conveyor transports the asparagus to a collection unit. An operator sits at the rear of the machine to transfer the asparagus from the collection unit into storage crates.

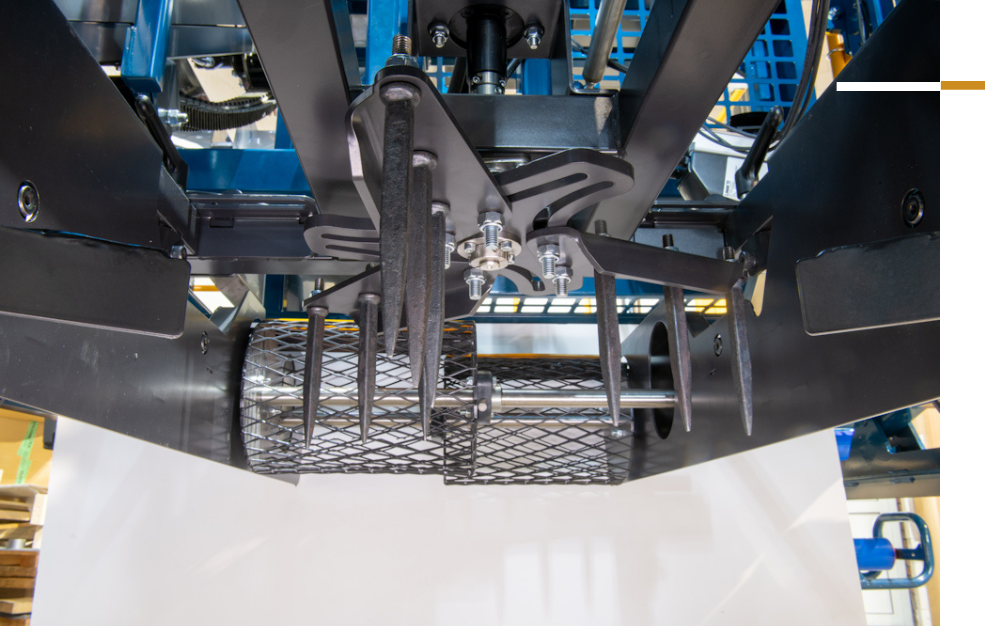

Sand bed repair

The hole that is left behind in the sand bed is repaired by the sand bed repair module which ensures that the sand bed remains fully homogenous throughout the season. Sparter removes the plastic film from the sand bed in front of the machine and puts it back into place after picking.